The motor and actuator selection behind each wheel can make or break the success of the entire system. In this post, we'll explore the core challenges in mobile robot drive systems and how customized motion control solutions from DINGS' Motion USA can help you meet them.

Optimizing Wheel Drives for AGVs and AMRs: What OEMs Need to Know About Motion Control

Article from | Dings' Motion USA

As demand grows for mobile automation in warehouses, hospitals, and factories, AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) are becoming a cornerstone of industrial efficiency. Whether you're transporting medical supplies across a hospital floor or moving pallets in a fulfillment center, the performance of these vehicles depends heavily on one critical element: the wheel drive system.

For OEMs designing AGVs and AMRs, the motor and actuator selection behind each wheel can make or break the success of the entire system. In this post, we’ll explore the core challenges in mobile robot drive systems and how customized motion control solutions from DINGS' Motion USA can help you meet them.

The Challenge: Compact, Precise, and Efficient Motion

AGVs and AMRs must navigate dynamic environments with high accuracy and minimal downtime. This creates a unique set of engineering demands:

-

Space Constraints: These vehicles often require motors that deliver high torque in a small footprint to maintain a compact design.

-

Battery Life: Efficient energy use is key to maximizing uptime between charges.

-

Load Variability: The drive system must maintain smooth, controlled motion—even as load weight, terrain, and speed requirements change.

-

Thermal Management: Continuous operation generates heat that can affect performance and longevity if not properly managed.

-

Navigation & Safety: Real-time feedback from wheel drives ensures accurate movement, braking, and obstacle avoidance.

Meeting all these needs requires a motion solution that’s more than just off-the-shelf.

Matching the Right Motor and Drive System to the Job

A successful AGV or AMR starts with selecting the right motor technology for the drive system. Here's how different options compare:

Here's how different options compare:

-

Brushed DC Motors

Cost-effective and simple to control, but limited in life span and not ideal for continuous-duty or maintenance-sensitive applications. -

Brushless DC (BLDC) Motors

Offer long life, high torque density, and excellent efficiency. Paired with encoders, they deliver precise control at variable speeds—ideal for mobile robotics. -

Gear-integrated Motor Systems

Add planetary gearboxes to reduce speed and boost torque, enabling smaller motors to handle heavier loads. -

Closed-Loop Feedback Systems

Incorporating encoders allows for real-time speed and position feedback. This is essential for tasks like coordinated motion, turning, or docking with charging stations.

At DINGS' Motion USA, we specialize in helping OEMs strike the right balance between torque, size, cost, and efficiency—often through custom winding configurations, housing adjustments, or feedback integration.

DINGS' Motion USA: Custom Wheel Drive Solutions Built to Perform

We don’t believe in one-size-fits-all. Our team partners directly with OEMs to develop wheel drive systems optimized for your specific AGV or AMR application.

Here’s how we deliver value:

-

Compact, High-Torque BLDC Motors

With integrated planetary gearheads for mobile robots that need power in tight spaces. -

Dual Encoder Options

For applications requiring both motor shaft and wheel position feedback, improving navigation and obstacle handling. -

Custom Winding and Housing Designs

That reduce current draw and improve thermal efficiency—extending battery life and uptime. -

Integrated Controller Compatibility

Ready-to-pair solutions with servo drives or motion controllers for smooth integration into your platform.

Our products are already in use across mobile robot platforms in life sciences, logistics, and manufacturing—trusted by OEMs who need reliable, responsive drive performance.

Ready to Build a Better Wheel Drive?

Choosing the right motor and actuator solution for your AGV or AMR can unlock better performance, longer runtime, and safer operation. With deep engineering expertise and a commitment to customization, DINGS' Motion USA is ready to help you take your mobile robot to the next level.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

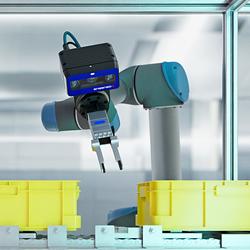

Featured Product