Different plants require a different amount of light for healthy crop production. High-light crops, such as tomatoes, peppers, and cucumbers require a high Daily Light Integral (DLI). Both their quality and yield depend on them getting enough light throughout the day.

The Importance of DLI and Light Quality

The Importance of DLI and Light Quality

Article from | Heliospectra

Different plants require a different amount of light throughout the day for healthy crop production. High-light crops, such as tomatoes, peppers, and cucumbers require a high Daily Light Integral (DLI). Both their quality and yield depend on them getting enough light throughout the day. In fact, tomatoes and peppers require a DLI of 22-30 moles per day to produce high-quality plants. Compare this to low-light crops like ferns that need only 6-10 moles per day.

What is DLI?

In a greenhouse environment, the natural light shining into your facility and the supplemental light you provide to plants in a 24-hour day make up the total daily light integral. It encompasses the light within PAR (Photosynthetically Active Radiation), in the blue, green, and red range of the spectrum (400-700 nm), that plants use for photosynthesis.

Why is DLI Important?

DLI influences plant growth, development, yield, and quality. For example, DLI can influence the root and shoot growth of seedlings and cuttings, impact characteristics like branching, flower number, and stem thickness, as well as speed up or slow down production.

Different plant species have different light requirements at each stage of development. Keep in mind that since DLI is dependent on both photoperiod and intensity, when both light levels and day length are reduced during the winter period the DLI will decrease considerably. Under such conditions, supplemental lighting not only needs to be at the right intensity and photoperiod but also attention to light quality may be of importance to ensure that plant quality is achieved.

Importance of Light Quality

Light gives plants the energy they need for photosynthesis, which converts that light energy into sugars to fuel growth and development. In addition to the quantity (intensity) and duration (photoperiod) of light you provide to plants, the quality of the light (spectrum) is also important. Broad-spectrum LEDs are available that offer an extensive variety of wavelength combinations to meet specific growth goals. Such LEDs can be controlled to deliver the ideal light to suit the application, such as supplementing the natural light plants receive in a greenhouse or providing a balanced broad spectrum that replaces natural sunlight in a sole-source indoor growing environment.

The light spectra can also be tuned to individual crop needs. For example, blue light is associated with decreasing plant stretching, green light is known to reach further into the canopy and can prevent inner leaves from yellowing, red light is known to stimulate photosynthesis, while far-red is known to help promote growth and flowering. This is just a small sampling of what controlling and balancing the different wavelengths of light can achieve. To learn more, see our infographic.

Light Conditions in a Greenhouse

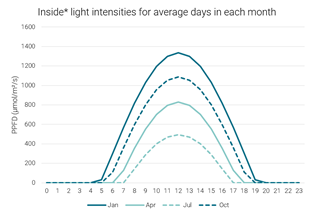

Light can be one of the most limiting factors for crops, and this is especially true for high-light crops in a greenhouse, where seasonal variations and limitations may inhibit crop productivity. During the winter months, natural light levels are often low, which means fewer hours of light combined with lower light intensities (see below).

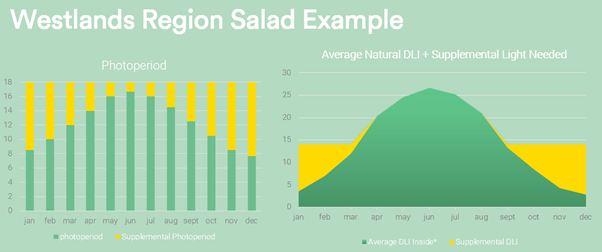

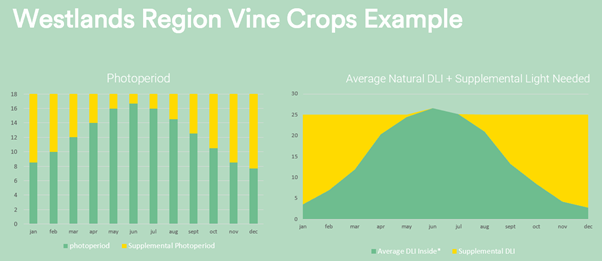

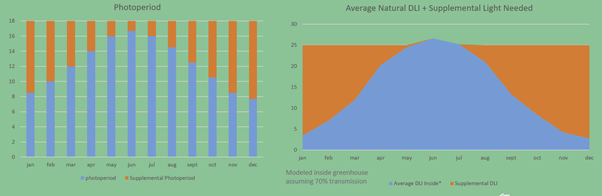

Example DLI Australia

DLI Control in a Greenhouse

As mentioned above, in a greenhouse the DLI is the sum total of the natural light and the supplemental light that reaches your plants. Together, these need to provide a consistent DLI for your crops year-round to ensure consistent production 365 days per year. When controlling the supplemental lighting in your greenhouse, you need to consider the natural light levels in your facility, the geographic region, the season, the time of day, the light transmission factor coming through the glass, and even the shade cast from the structure. There are many things you can’t control when it comes to greenhouse lighting, but what you do have the opportunity to control is your supplemental lighting, such as using intelligent LEDs with predictive lighting control technology. Heliospectra’s helioCORE™, for example, can predict how your lights should be used to provide your DLI target in the most efficient way over the given photoperiod. The DLI controller will ensure that the crop receives the right amount of total light over the photoperiod (see below) without overusing the lamps and wasting energy.

LED Lighting Control Opens Up More Possibilities

LEDs are known to produce less heat than traditional lighting technologies like HPS, which means that there is the potential to use LEDs in greenhouses in warmer climes. Due to their controllability, LED lighting can provide the right amount of light throughout the year, even for the most light-hungry crops, adjusting for shoulder parts of the day or seasons, for year-round consistent production. If you would like to know more about horticulture lighting control, sign up for a free demo of helioCORE™. helioCORE™ Demo

- Palmitessa, Onofrio D., Marco A. Pantaleo, and Pietro Santamaria. 2021. "Applications and Development of LEDs as Supplementary Lighting for Tomato at Different Latitudes" Agronomy 11, no. 5: 835. https://doi.org/10.3390/agronomy11050835

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product