The LemnaTec system, called Scanalyzer3D, utilizes advanced cameras from Allied Vision to provide researchers with previously unavailable data on plant growth, root development, water absorption and drying, and photosynthesis.

Researchers Analyze H2O Absorption via Goldeye SWIR Cameras

Researchers Analyze H2O Absorption via Goldeye SWIR Cameras

Case Study from | Allied Vision

In a world with a rapidly rising population, ongoing climate change, and diminishing agricultural resources, Allied Vision is helping LemnaTec GmbH build innovative laboratory automation systems that guide researchers on how to optimize crop yields.

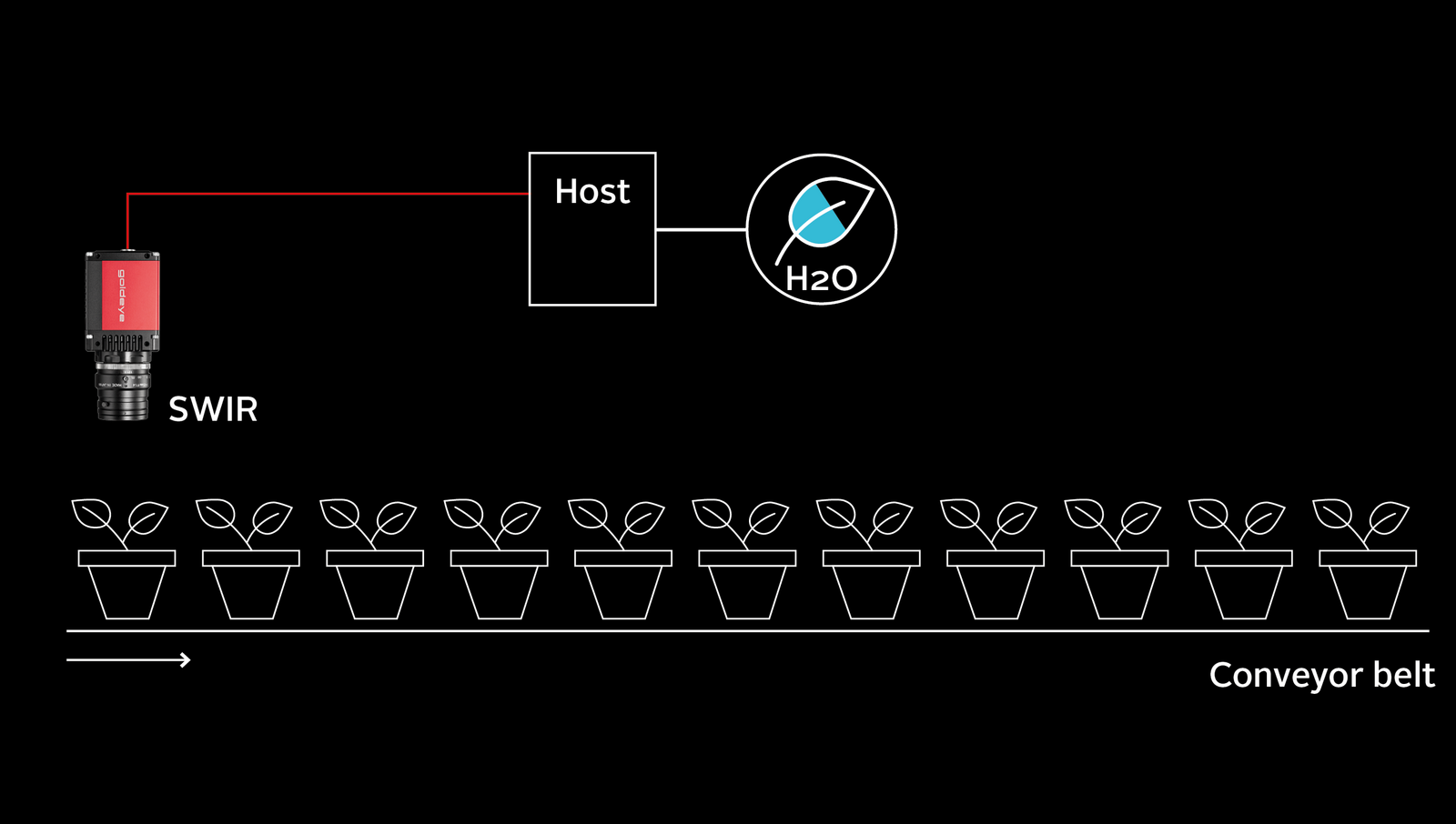

The LemnaTec system, called Scanalyzer3D, utilizes advanced cameras from Allied Vision to provide researchers with previously unavailable data on plant growth, root development, water absorption and drying, and photosynthesis. This breakthrough results from how the cameras employ infrared light to obtain finely detailed images of how plants use water.

The challenge

Crop yield optimization

Much of the crop research focuses on grains, the world’s primary source of nutrients. Different types of grains are being hybridized and cultivated to achieve optimal yields with a minimum use of resources. In the process the plants are examined with sophisticated laboratory technology from companies such as LemnaTec GmbH in Aachen. Scanalyzer3D is a highly automated testing system with which quantitative, nondestructive measurements can be performed on cultivated crops in greenhouses. Plants pass through a series of optical measuring spaces in which they are imaged using various wavelengths. This allows the system to recognize much more detail than the human eye can see—and in more detail than was possible with other methods. Each plant passes through a series of measurement stations and the series is repeated at various stages of the plant’s growth cycle, so researchers can collect statistically relevant, comparable data over time.

At one of these stations, roots are imaged with the aid of infrared cameras operating in the shortwave, near-infrared range, documenting moisture absorption and with it the root system’s efficiency. At another station, the section of the plant above the soil is analyzed in the same manner. The images provide information on the water content of the stem and leaves, and, by extension, on the drying process as well as the plants’ recovery following drought.

The solution

SWIR camera highlights water content

Of particular interest for bio scientists is the use of infrared cameras in the lowinfrared range (900-1,700 nm), also known as SWIR (Shortwave Infrared). With this technology, a plant’s moisture content, or the water distribution within the plant, can be highlighted. Because water strongly absorbs infrared light in a wavelength range from 1,450 to 1,500 nm, it appears black and opaque in an infrared image, so that aqueous areas within a plant appear correspondingly darker. Thanks to this property, scientists can precisely follow water absorption from the roots into the leaves. Conversely, evaporation and desiccation can also be visualized.

For these measurements (in Stations 3 and 4 of the Scanalyzer3D), LemnaTec relies on Allied Vision's infrared Goldeye cameras. With its InGaAs (indium gallium-arsenide) sensor technology, the Goldeye is sensitive in the SWIR range, thus precisely capturing the spectral range in which water absorbs infrared light most strongly. The Goldeye distinguishes itself with its outstanding image quality that allows for especially precise measurements, provided by active sensor cooling using a thermoelectric module (TEC) and innovative image correction algorithms that optimize images within the camera.

The benefits

Innovations in agriculture and agronomy

The data captured by the cameras is analyzed and processed by LemnaTec’s software, LemnaGrid. Thanks to its graphical user interface, LemnaGrid is extremely intuitive to operate. Users can design their imaging processes even if they have no programming skills. False color renderings help illustrate the results in the captured images. Additional tools such as LemnaMiner and LemnaShare ease data export and exchange for further processing by a research team.

With Scanalyzer3D, LemnaTec helps scientists at the most renowned public and private research institutions develop the next innovations in agriculture and agronomy. Among their clients are BASF, Bayer Crop Science, DuPont, and international research institutions such as ACPFG (Australia), ICAR (India), and the French national agricultural research institute, INRA.

The camera: Goldeye SWIR G-032

Low-noise image quality

The Goldeye G-032 TEC1 is a very versatile shortwave infrared camera for the spectral range from 900 nm to 1700 nm. High frame rates of 100 fps at full resolution (636 x 508), strong sensor cooling, as well as a high intra-scene dynamic range of more than 73 dB enable to apply the camera in various application areas and under varying operating conditions. The integrated thermo-electric sensor cooling and several on-board image correction features contribute to the Goldeye's outstanding image quality.

Highlights at a glance

- With SWIR cameras plant’s moisture content can be highlighted.

- Goldeye is sensitive in the wavelength range from 1,450 to 1,500 nm in which water absorbs infrared light most strongly.

- Valuable insights in how to optimize crop yields and develop the next innovations in agriculture and agronomy

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product